-40%

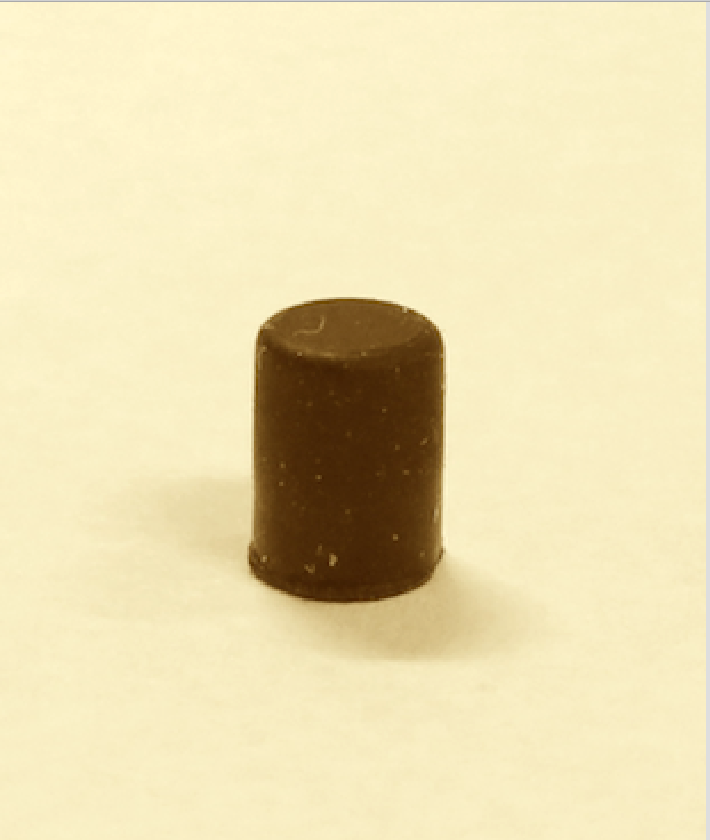

NEW IDLER WHEEL LENCO L 70 BOGEN B72-62 LENCO GOLDRING 88 LENCO 99 SHAFT 3mm

$ 34.32

- Description

- Size Guide

Description

BEWARE OF IMITATIONSAudiosilente parts are produced using CNC lathes designed for medical and dental applications

No one offers tighter tolerance parts than Audiosilente

Audiosilente, based in Rome, Italy, utilizes CNC Dental Lathes to produce a line of tight tolerance, precision-machined replacement parts for a variety of audiophile turntables from Thorens, Garrard, Rega, Lenco, Technics and others. We strive to produce parts that are true to the original design, that meet or exceed OEM specifications, but most of all, that will improve the performance, the sound of your prized turntable.

THREADED SHAFT 3MM

TH

E AUCTION IS FOR ONE NEW IDLER WHEEL

MADE IN ITALY

MADE IN ROMA

AUDIOSILENTE FACTORY.

FOR LENCO TURNTABLE

LENCO L 70 ( BOGEN B72)

LENCO GOLDRING 88 LENCO 99

FOR ALL LENCO WITH

SHAFT THREADED

3 MM

IF YOUR LENCO TURNTABLE

HAS SHAFT WITHOUT THREADED

THIS IDLER WHEEL IS NOT CORRECT

THE HOLE OF IDLER WHEEL IS 3.00 MM

IF YOU WANT THE IDLER WHEEL FOR SHAFT 2.45MM

LOOK MY OTHER AUCTION.

IDLER WHEEL WITH O- RING.

IDLER WHEEL + 2 BLACK O RING +

+

EXTRA 1 SILICON RED O -RING.SIZE 3200

+2 SILICON RED O -RING SIZE 4200

FOR LENCO TURNTABLE.

TOTAL 5 O-RINGS

THESE O RINGS ARE MADE FOR AUDIOSILENTE

I PREFER THE SOUND AND DINAMIC OF RED SILICON O- RING.

WE HAVE CONDUCTED MANY EXPERIMENTS AND THE SILICON O RINGS

IS THE BEST MATERIAL FOR RUMBLE.

OTHER MATERIALS AS THE POLYURETHANE, NEOPRENE, INCREASE THE RUMBLE

WE HAVE CONDUCTED MANY EXPERIMENTS AND THE SILICON O RINGS

ARE THE BEST MATERIAL FOR RUMBLE.

THE SILICON O RINGS ARE PRODUCED FOR AUDIOSILENTE

OTHER MATERIALS AS THE POLYURETHANE,

NEOPRENE, INCREASE THE RUMBLE

AND CREATE FLUCTUATION IN THE SPEED '

AUDIOSILENTE IDLER WHEEL IS THE BEST IDLER WHEEL

FOR YOUR LENCO

BEWARE OF IMITATIONS

THE NEW IDLER WHEEL IS MORE GOOD THAN ORIGINAL .

.

MADE IN ITALY

MADE IN ROME

WITH CNC MACHINE LATHE

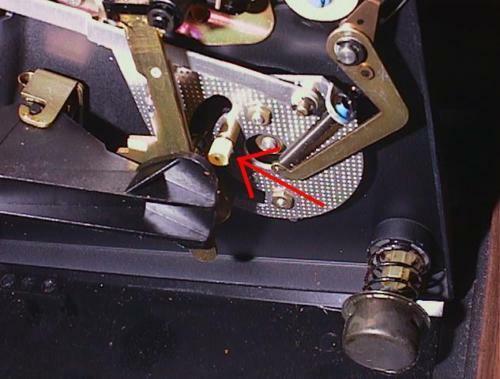

Remove the bracket that supports the pulley and release the spring.

Assembling procedure

Remove the old pulley; clean the rolling pin with a cloth and alcohol and degrease the new pulley with alcohol. Check that the red standard o-ring fitted on the new pulley is not looped and rolled up.

Mount the new pulley reassembling the sealing ring and check that it does not block the correct rotation of the pulley.

Then put a drop of synthetic oil in the seat of the bearing of the pulley.

The bushing has tolerance next to hundredth, and as a consequence it needs to running-in.

The black o-ring generates a plate soft start, while the o-ring red silicone determines an instant start and

AUDIOSILENTE